Partner’s Portrait: SINTEF

SINTEF is one of Europe’s largest research institutes, with multidisciplinary expertise within technology, natural and social sciences. As a Norwegian R&D partner, SINTEF strives to contribute to value creation and increased competitiveness within the public and private sectors. With around 2000 employees, SINTEF delivers applied research, innovation, technological development, knowledge, and solutions for customers across the world.

In the ReSoURCE project, SINTEF is participating through its Industrial Process Design (IPD) group located in Porsgrunn. The group has been working with powder and particulate technology for more than 40 years and successfully carried out several R&D projects funded by EU, the Norwegian Research Council and various industries. It has been serving several industrial sectors such as oil & gas, metals, minerals, engineering, chemical, fertilizers, FMCGs, pharmaceuticals, food, and feed. SINTEF IPD provides R&D services for the entire value chain of the processes, i.e., from lab experiments to industrial scale implementations via pilot tests.

SINTEF IPD aims to foster sustainable process industries by integrating state-of-the art process technologies with advanced digital solutions. Primary goals of its initiatives include enhanced safety and improved resource, energy, and cost efficiency across various industrial processes, particularly those involving powders and particulate materials.

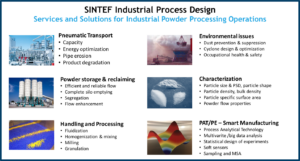

The powder handling and processing operations served by SINTEF IPD activities are presented in Figure 1.

Figure 1: Powder handling and processing activities at SINTEF IPD.

SINTEF IPD hosts the following pilot and bench scale test facilities:

- Pneumatic conveying pilot test rigs (dilute & dense phase)

- Powder Fluidisation test rigs

- Powder mixing units (batch & continuous)

- Sand blast type erosion tester

- Particle Comminution-milling

- Equipment for air classification & powder sorting

Additionally, its infrastructure to characterize various mechanical and materials properties of powders is as follows:

- Particle Properties (size distribution, densities, surface areas, flow properties)

- Flow properties (Jenike shear, uni-axial, angle of repose)

- Particle Shape Analyzer

- Revolution Powder Analyzer

- Evolution Powder Tester

- Sieving machine (120 µm – 2040 µm)

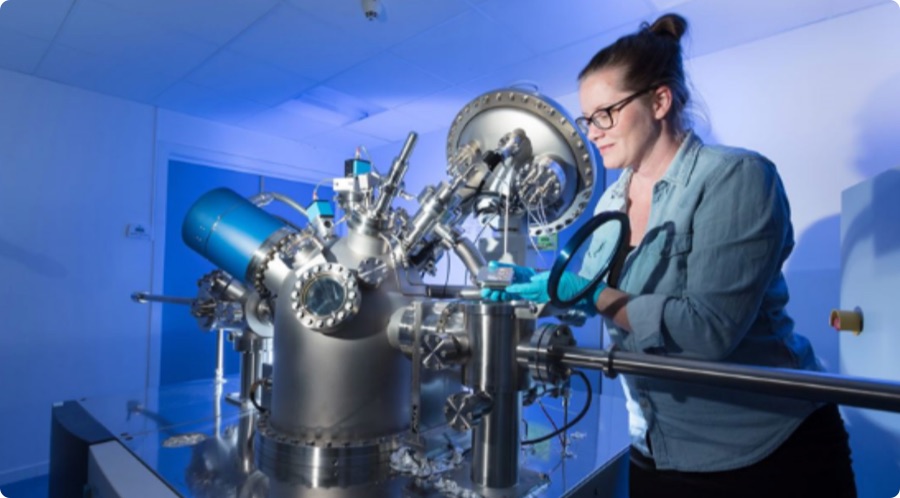

Some pictures of SINTEF IPD’s experimental facilities are presented in Figure 2.

Figure 2: Experimental facilities for powder processing and characterization at SINTEF IPD.

In recent years, the group has been involved with the following long-term projects:

- Refractory Sorting Using Revolutionising Classification Equipment (HEU Project GA No. 101058310)

- Open Innovation Digital Platform and Fablabs for Collaborative Design and Production of personalised/customised FMCG (EU H2020 Project, GA No. 870148)

- Improving Efficiency of Offshore Drill-cuttings Handling (NFR, PETROMAKS Project No. 234162)

- Effective Handling of Bulk Solids with Focus on Reduction of Erosion and Scale Formation (NFR BIA Project No. 247789)

In the future, SINTEF IPD intends to accelerate its activities on developing solutions for circularity of resources in process industries.

Partner