Let Them Shine in the Light of the Laser

The first set of samples, which is described in detail in this blog, has reached the Fraunhofer ILT. After looking through the hyperspectral glasses at NEO, the samples are analysed with laser-induced breakdown spectroscopy (LIBS) in Aachen.

The LIBS technology in simple words: We shoot a laser onto the sample surface, ignite a small part of it and look at the colour of the flame. And this colour allows us to draw conclusions about the probed material.

The LIBS technology in more detail: A nano-second laser-pulse (about 10 ns length, and ~100 mJ of energy, Q-switched Nd:YAG laser at 1064 nm) is focussed on the surface of a probe (laser-focus area is about 0.5 mm to 1 mm in diameter on a distance of ca. 70 cm). Due to the high energy supplied, a small amount of the sample material is melted, vaporized and a plasma is ignited from it (typically a few µg of the material). This plasma consists of the electrons, ions, and excited atoms of the sample material. Since the laser pulse is already over, it cools down again. Ions and electrons recombine, and excited atoms relax. The plasma emits radiation characteristic of the material. This is observed with a spectrometer (observed wavelength area ca. 250-550 nm with a resolution ~15 pm). The entire process takes maybe 10 ms. The result is a plasma emission spectrum in which emission lines can be assigned to elements. The intensity of an emission line can be used to determine the material content. On the sample, a small crater remains in which the material has been ablated by the laser.

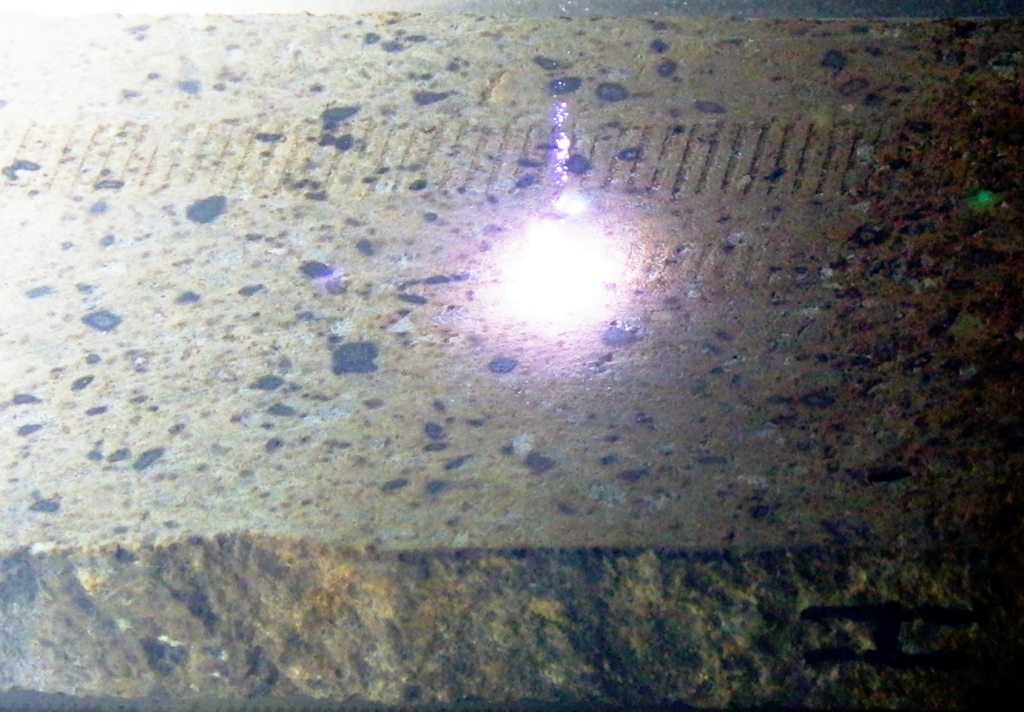

The picture shows an LIBS plasma on sample. Note that you can already see a slight coloration with the naked eye. Behind it you can see craters of past analyses.

This analysis is carried out locally on the surface. By repeating the analysis at the same point, the crater can be deepened, for example, to remove surface layers and gain information about underlying materials; by repeating the analysis on other points, the entire surface of the sample can be analysed. In the first step, we make a fine resolution grid analysis of each unused refractory brick in a manageable area and of each used brick an analysis across the brick from the hot to the cold side. This helps us to understand the different compositions and material changes during application in order to be able to correctly recognize all materials afterwards, whether new or old, whether fine or coarse-grained, whether dirty or clean.

At this stage of the project, we are still working on LIBS analyses in the laboratory, but the technology is in principle also suitable for use in industrial environments with moving and contaminated samples. We will demonstrate this later on in the project.

Frederik Schreckenberg M. Sc.

Frederik is a research associate at Fraunhofer Institute for Laser Technology ILT. He studied physics at RWTH Aachen University. His research interest are material analyses, recycling and resources as well as data science.

Partner